Page 6 - Vira Filter Digital Catalouge

P. 6

Diffusion Media FF-560 GX

DESCRIPTION APPLICATIONS

Fine air filtration media specifically designed to be used in This high quality Ceiling Diffusion media is specially designed

down-draft paint spray booths as final filtration barrier to all to be used in the ceiling of paint spray facilities in auto assembly

paint damaging particles from the intake air stream. This Ceiling plants and down draft spray cabins in auto refinishing facilities

Filter or Diffusion media ensures a uniform air distribution and as well as in paint spray booths of the repair after markets.

a laminar flow throughout the spray booth, when applied in This media enhances a uniform air distribution and a laminar

auto assembly plants and auto refinishing facilities as well as airflow. Further, it acts as the final filtration barrier to paint

in the repair after markets. damaging particles from the air stream which is an absolute

Synthetic fiber-based filter media developed and manufactured requirement for high gloss and high-tech performance finishes.

at high-tech media plant based in The Europe.

The filter media is constructed from selected high performance,

nonbreakable fibers in a progressive density multi-layering

technique allowing high depth loading to ensure high dust holding

capacity with optimal lowest pressure drop performance.

This media is thermally bonded and impregnated in full depth

with a special tackifier coating to prevent any release of fibers

and migration of paint damaging particles larger than 10 microns

due to vibration in the system, even under varying temperature

conditions.

FF-560 GX is classified as R0 in accordance with the migration

test.

This results in high fractional efficiency combined with a high

dust hoading capacity, a long filter life as well as low energy

and maintenance costs.

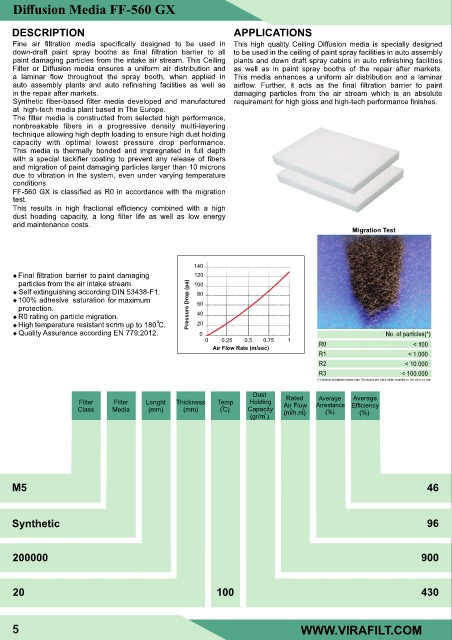

Migration Test

140

Final filtration barrier to paint damaging 120

particles from the air intake stream. 100

Self extinguishing according DIN 53438-F1. 80

100% adhesive saturation for maximum Pressure Drop (pa) 60

r p otection.

R0 rating on particle migration. 40

High temperature resistant scrim up to 180 C. 20

Quality Assurance according EN 779:2012. 0 No. of particles(*)

0 0.25 0.5 0.75 1

R0 < 100

Air Flow Rate (m/sec)

R1 < 1.000

R2 < 10.000

R3 < 100.000

(*) Number of particles larger than 10 microns per cubic meter counted on the clean air side

Dust Rated

Average

Average

Filter Filter Lenght Thickness Temp Holding Air Flow Arrestance Efficiency

Class Media (mm) (mm) ( C) Capacity 3 2 (%)

2 (m/h.m) (%)

(gr/m )

M5 46

Synthetic 96

200000 900

20 100 430

5 WWW.VIRAFILT.COM